Damage Bergen diesel of a seagoing tanker

On arrival at Mossel Bay anchorage, South Africa, portside main engine, of an unloaded seagoing tanker of a Dutch shipping company, automatically shut down due to low lube oil pressure, followed by a black-out. The cartridges of the duplex lube oil filter of portside main engine were dismounted and serious damage to one of the cartridges was found. The crankcase of portside main engine was opened and it was found that at least one big end bearing was ran out. Vessel’s Managers it was decided to tow the vessel to Durban, South Africa for repairs.

We were appointed on behalf of Norwegian Hull & Machinery as well as Loss of Hire Underwriters of the vessel through a British broker. Several surveys at Durban were conducted over a period of seven months. During which period both Rolls-Royce Azimuth thrusters were completely overhauled due to damages also.

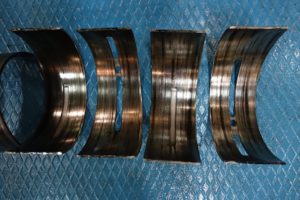

It was found that all crankshaft bearings of the Bergen diesel with an output of 3.600 kW at 720 rev./min. had ran out and as a result the crankshaft was beyond repair. Repairs were follow-up by us and repair cost were assessed and reported.

After thorough investigation and interviewing the crew, we concluded that damage was the consequence of faulty assembly of the duplex filter unit during last maintenance.

Such an assignment is handled very regularly by Verschoor & Bras in sea and inland shipping.